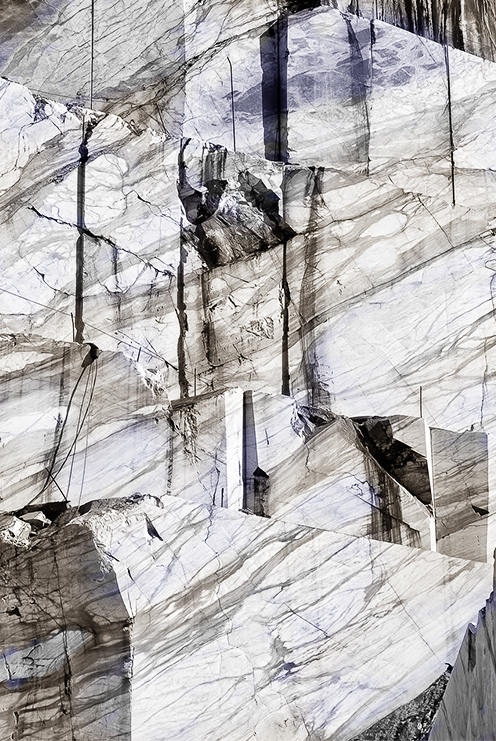

The Apuan Alps, an unspeakably beautiful landscape of rocky summits and pointed ridges, formed hundreds of millions of years ago from slow but violent tectonic jostlings that brought to surface what had been at the bottom of a primordial sea. Lithified fossils and biological debris of tiny death creatures drifted slowly and accumulated, along with other minerals, to form limestone. The calcite found on limestone, subsequently subjected to heat and high pressure from convergent tectonic plates, recrystallized to form metamorphic rock.

Marble, a pristine white stone made of small sparkling crystals mixed with other complex mineral structures, formed with such striking and colorful stratifications in some portions of these mountains, that the locals would name it a specific word - Calacata.

The Calacata Borghini quarry, in the heart of the Apuan Alps. © ETAMORPH

The gold veins of the mountain. © ETAMORPH

The entrance of the Borghini Quarry. © ETAMORPH

Our journey starts in one of the oldest quarries, renowned for the stone’s spectacular gold veins and its unique crystal structure which gives the marble a delicate translucency. The Calacata Borghini quarry (Cava Ruggetta), in the heart of the Apuan Alps, extracts an astonishing variety of marble that ranges from pure white with large gold veins to blueish-grey with white veins.

Although the methods of extraction have drastically changed over the centuries, the main process remains: large and small blocks of stone are cut in the quarry and hauled down on the plain to be further processed.

Marble blocks in the stone yard, before to be futher processed. © ETAMORPH

The selection of the material is a key step in the design process and it is done through an old yet efficient method. Walking through the blocks, the surfaces are sprayed wet to restore the original vividness of the colorful pattern that is hidden beneath the coarse surface of the stone block.

When the design is conceived from a flat slab, the gallery is the place to start the research. Like in an art gallery, where the paintings are arranged in order to enhance the visitor’s experience, the marble slabs are organized in a series coming from the same block. As radiographies, they show the essence and history of the mountain, deposited in layers of millions of years.

Calacata slabs in the stone gallery. © ETAMORPH

Once the material has been selected, the future of the project is in the hands of expert fabricators dedicated to our craft. The stone workshop is the place where the idea takes its first physical shape as a prototype.

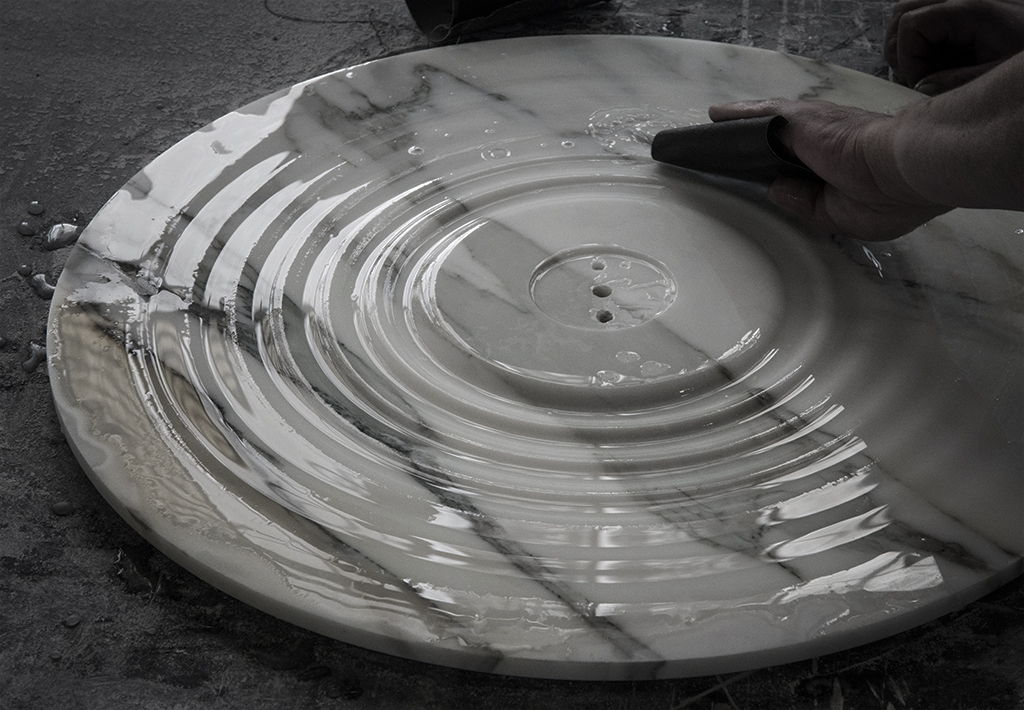

Here, special abilities and knowledge in stone working, passed down through countless generations, have reached the pinnacle of quality and precision. Combining cutting-edge technologies such as 5-axis CNC machining, water-jet cutting, block saws and lathes with traditional craftsmanship methods, the marble is worked to the limit of its possibilities.

The stone workshop in Carrara. Marco Buratti Photography

Stone working with a lathe. Marco Buratti Photography

Rarely has the extraction of a material been so difficult and yet so precisely done. Each move has to be thoroughly thought out before any decisions are made. Every modification to its shape challenges its nature, from the instant that it is wrenched from the mountain to the finest fabrication detail.

Aura and Messier are the outcome of this complex and unique process. Two projects that reinterpret the characteristics of an extraordinary stone through the use of the most advanced fabrication techniques and expertise.

Messier marble lamp - CNC machining on the surface. Marco Buratti Photography

Messier marble lamp - Hand sanding. Marco Buratti Photography

Messier marble lamp - Final hand finishing. Marco Buratti Photography

The ripple effect on the surface of Messier marble sconce is the result of a remarkable combination of 3D modeling, Computer Numerical Control machining and several stages of hand finishing. The concentric waves reverse the perception that we commonly have of a hard material like natural stone - no longer static and hard but soft and fluid, istead.

The monolithic cylinder that covers Aura lamp is sculpted from a single block of Calacata Borghini marble and worked through a precise sequence of special machines . The final design reverses the original characteristics of the starting material - no longer solid and straight but hollow and curved, instead.

Aura lamp - Block saw. Marco Buratti Photography

Aura lamp - Lathe finishing. Marco Buratti Photography

Once finished, the marble components are assembled with the rest of the lamp and lit up. Thanks to the translucency of the stone, the light is softly released through the surface playing gently with the ripple effect on the disc or emanating sharply through the vertical cuts of the marble cylinder.